Not Your Ordinary Satellite Manufacturer

Why Reflex? Because You Should Never Sacrifice on Performance or Speed

Classic Space satellites are not known to be developed fast, and NewSpace satellites tend to struggle to deliver high performance and reliability.

Reflex tackles both. We design every satellite around the needs of our customers and we never compromise when it comes to power, performance, or reliability.

The customizability of classic space meets the speed and innovation of NewSpace.

We call it NextSpace®

We Have A Need For Speed

Our goal is to get you from contract signature to satellite in 12 months. Have a complicated payload? Even better. We love a challenge, and our fully-customizable OmniFlex platform can host even the most demanding payloads. We encourage you to reach out so we can talk about how to make your vision a reality.

Mass Customization is our Speciality

Our unique technology mix allows us to mass customize high end satellite platforms for our customers. We do this through thoughtful and purposeful design. Choosing Reflex to manufacture your satellite means you get access to unique advantages.

MICROFACTORY CAPABILITIES

Our ability to make custom platforms at scale means that you can get exactly what you want, and we can make it fast. And for those who require sovereign assembly, our Reflex MicroFactory can be built around the world based on you specific needs.

ITAR Free

Reflex only uses ITAR-free satellite components to cut down on bureaucracy, reduce lead time, and improve our outcomes.

PURPOSEFUL VERTICALIZATION

We have brought key elements of the manufacturing process under our control to achieve the best mix of performance and speed.

High Performance Platforms

We apply cutting-edge commercial manufacturing techniques to satellites, dramatically decreasing assembly and integration times.

By applying generative design, additive manufacturing, and streamlined system design processes, Reflex accelerates satellite delivery.

We prioritize customer mission objectives which offers them the opportunity to get their payload to orbit without compromises.

-

Power from hundred of watts to several kilowatts. We can accommodate even very power hungry payloads.

-

Reflex ARC (Autonomous Reconfigurable Computer)

Multi-core ARM-based Architecture

1 TB Redundant Storage

-

TMTC: S-Band

Payload data: X-band (baseline), optional:

Optical Data Links

High-throughput Ka/Ku-Band RF

-

Tailored thrust and delta-v solutions for any mission profile

-

Agile 3-axis stabilized architecture

Achievable performance up to:

< 0.01 deg (3σ) pointing accuracy

< 0.005 deg (3σ) pointing knowledge

< 1 m position knowledge in orbit

-

In-orbit image processing, analysis, and feature-detection ready

SW-defined architecture

Single and multi-mission ready

Learn How to Buy a Satellite

It’s easier than you think. When you reach out to Reflex, you can expect a quick response from our team. Watch the video to learn more:

Never Standard. Always Custom.

MASS CUSTOMIZABLE

Each satellite is not only tailor-made for your payload and mission, but designed in a way that we can deliver one satellite, or an entire constellation.

MULTI-MISSION CAPABLE

Have more than one payload? No problem. Our platform allows for multiple missions on one satellite.

Access to a

Deeply Talented Team

Choosing Reflex Aerospace for your custom satellite needs means gaining access to the best engineering talent in both classic and NewSpace. Together, our team became the fastest and leanest class to achieve flight heritage.

60+

TEAM MEMBERS

45

MISSIONS’ EXPERTISE

18

NATIONALITIES

Our Locations

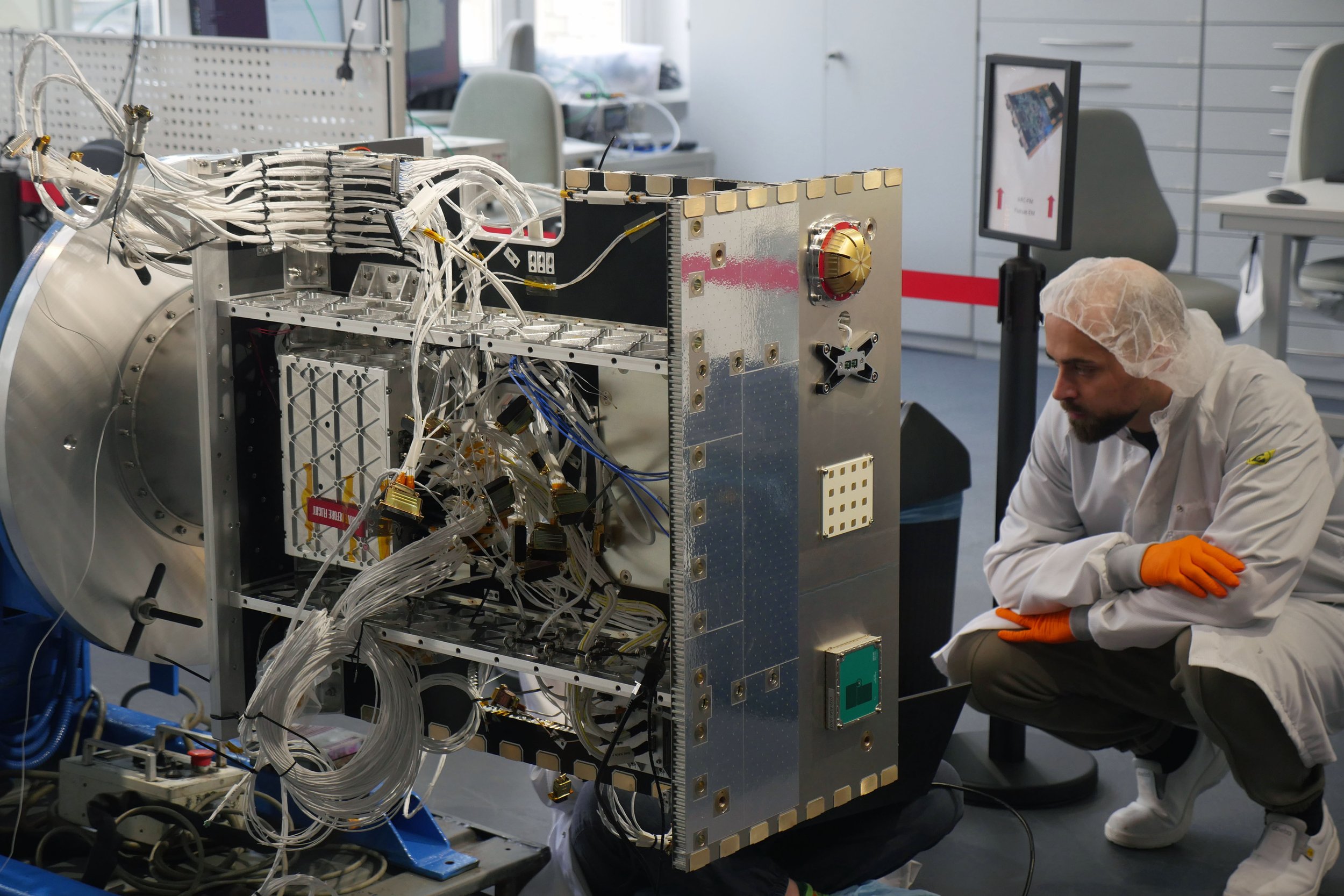

Berlin

Electronics laboratory

Mechanics workshop

Mechanical and electrical ground support/testing equipment (MGSE/EGSE)

High-level onsite and cyber security systems

PROTOTYPING | DESIGN | SOFTWARE

Munich

MANUFACTURING | ASSEMBLY | INTEGRATION | TESTING

200 m2 assembly floor

ISO 8 clean room

Cell manufacturing concept

200 m2 additional assembly space

High-level onsite and cyber security systems

Co-located on IABG premises